Now multiply this number by the total length of the duct bank.

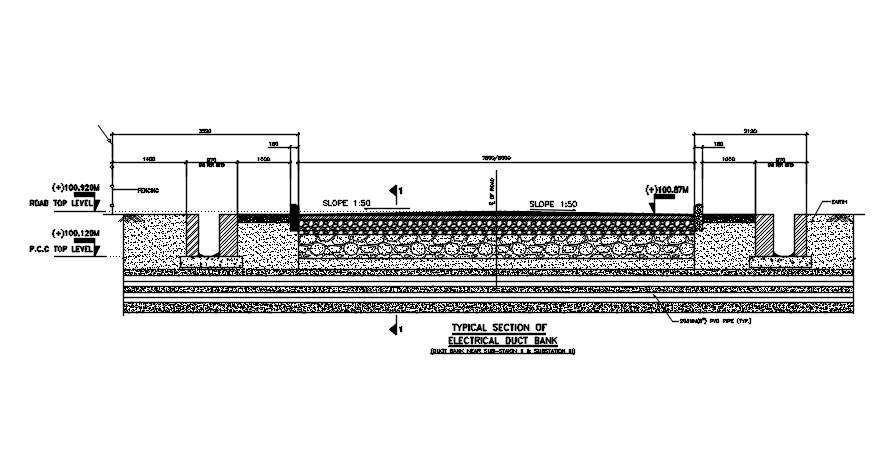

By dividing 462.96 by 144, the result is 3.215 square feet. Watch as an electrical contractor pours concrete into a ditch to provide 2' of concrete protection around each HV conduit, but obviously not doing so. This is the cross-sectional area occupied by the concrete alone.Ĭonvert the cross-sectional area occupied by the concrete from square inches to square feet by dividing that number by 144. So, 576-square inches minus 113.04 square inches equals 462.96 square inches. Subtract this number from the total cross sectional area of the duct bank. For a three-by-three, that is 3.14 times 4 times 9, which equals 113.04 square inches. The conduit area is pi times the radius squared times the number of conduits. The conduit area would be the cross-sectional area of one conduit times the number of conduits. Duct banks may carry cable a short distance, such as under a road or longer distances, such as carrying electrical power from a power generating source to transmission stations, industrial and public facilities. Now subtract from this number the total area occupied by the conduit. The cables are housed within PVC pipe called conduits, which are then encased in steel reinforced concrete. In this three-by-three example, that would equal 24 inches times 24 inches or 576 square inches. Multiply the total width and total height. Since this is a three-by-three duct bank, its height will also be 24 inches.Ĭalculate the cross-sectional area of the duct bank. Repeat step 2 using the number of vertical conduits instead of the number of horizontal conduits. 1 Deliver, store and handle materials in accordance with Section 01610 –Basic Product Requirements.Calculate the total height of the duct bank. 1 Submit manufacturer’s test data and certification at least 2 weeks prior to commencing work. Alfred Miller Companies, in Louisiana is a leading manufacturer of industrial precast concrete duct banks serving the Gulf Coast. 1 Submit shop drawings for precast manholes in accordance with Section 01330 Submittal Procedures. Duct Spacers: For concrete-encased duct banks, BC Hydro designers shall follow the draft ES54 Section H standards and include new PVC type duct spacers. 965 LF Concrete Encased 4 schedule 40 PVC conduit, 650 LF Direct Bury 4.

Concrete encased duct bank install#

1 ASTM D1056, Specification for Flexible Cellular Materials –Sponge or Expanded Rubber. Furnish and install Type 1 manhole lateral of existing mainline ductbank. 2 CSA A23.1/A23.2, Concrete Materials and Methods of Concrete Construction/Methods of Test for Concrete.3 CSA G30.3, ColdDrawn Steel Wire for Concrete Reinforcement.4 CSA G30.5, Welded Steel Wire Fabric for Concrete Reinforcement.5 CSAG30.18, BilletSteel Bars for Concrete Reinforcement.3 American Society for Testing and Materials (ASTM). 1 CAN/CSAA3000, Cementitious Materials Compendium.

1 Codes and standards referenced in this section refers to the latest edition thereof.2 Canadian Standards Association (CSA). Plans call for a 'river' of concrete slurry to encase the conduit w/6' of slurry all around. The typical conduit has 4 - 750 KCMIL and 1 - 4/0 GND. 1 Section 01330 Submittal Procedures.2 Section 02581 Excavating, Trenching and Backfilling.3 Division 3 –Concrete, Sections 03100, 03200 & 03300.4 Section 16010 –Electrical General Requirements.5 Section 01355 –Waste Management and Disposal. The common duct bank from the service yard to the building has up to 20 - 4' conduit (incl spares)in five groups of 4's with 24' spacing in between and 18' cover. DTW Works Master Specification Issued 1 Section02581Concrete Encased Duct Banks and Manholes of 6 PART 1 GENERAL 1.1 RELATED SECTIONS.

0 kommentar(er)

0 kommentar(er)